Econic 2635 as a future-proof industrial fire-fighting vehicle for the factory fire brigade in the truck assembly plant in Wörth.

Fire protection, hazard control and rescue – true professionals who are prepared for every eventuality are required for the many different tasks of the factory fire brigade in the world’s largest truck assembly plant: in Wörth am Rhein the fire-fighters are responsible for the safety of more than 10,000 employees and a factory covering a surface area of more than 2,800,000 m2.

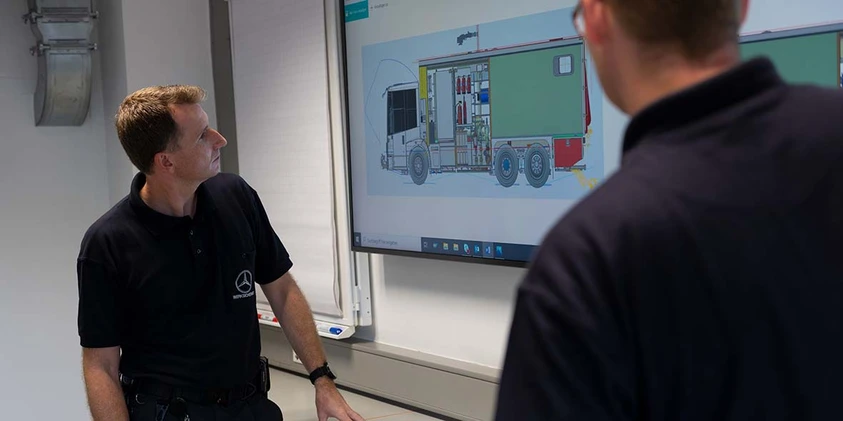

In the coming year the team of 34 and its fleet will be further reinforced by a professional from the factory’s own production line: the Econic 2635 will join operations as the new industrial fire engine. In a series of articles we will be accompanying the vehicle – from the precise planning stage to the moment it is officially handed over to the fire brigade.

Good planning instead of nasty surprises.

At present Sebastian Schröder, deputy station manager and Marc Knoll, deputy head of the factory fire brigade are involved in the planning phase for the bodies on the new Econic: they are responsible for the purchase of vehicles and the design of operating resources and as such must consider possible future operations as well as suitability for tackling daily challenges.